Basic knowledge of PLC includes understanding its function as a digital computer used in industrial automation to control machinery and processes by monitoring inputs, processing logic, and controlling outputs.

Knowledge of PLC is crucial in modern industrial automation. PLCs drive complex systems with flexibility and precision in industries like manufacturing and energy. To excel in PLC programming, a solid understanding of both the fundamentals and advanced knowledge tailored to industrial applications is essential. This article covers the critical knowledge you need and effective ways to develop expertise in PLC programming.

To add depth to the discussion, we interviewed Trevor Blevins, a seasoned industrial automation expert with over 20 years of experience in PLC programming and system integration. Trevor shared valuable insights into what it takes to master PLC programming.

Knowledge You Need for PLC Programming

Programming PLCs requires more than just coding skills. You need to understand the hardware and software aspects and their real-world applications.

Basic Understanding of PLCs

Interviewer: Trevor, for someone just starting, what foundational knowledge should they focus on in PLC programming?

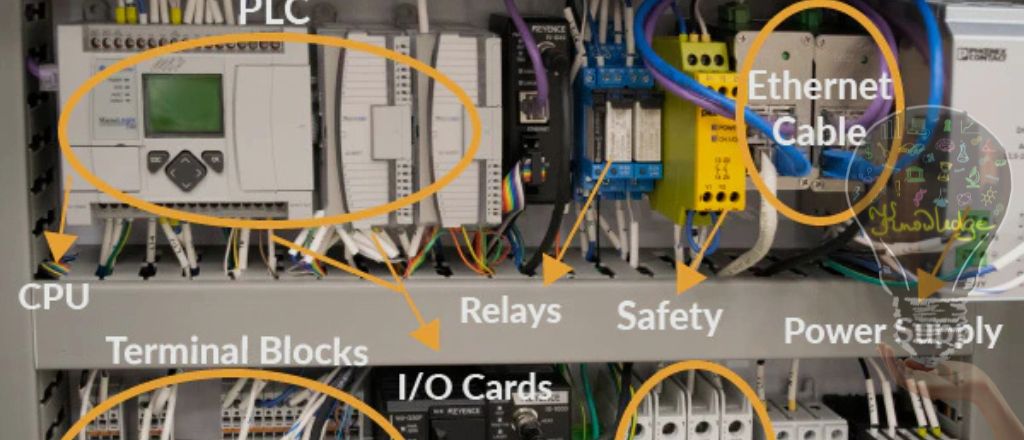

Trevor Blevins: First, understand what a PLC is and its role in industrial automation. It’s essentially the brain of automated systems. You must grasp its components, like the CPU, I/O modules, and power supply. Also, learn how it interacts with sensors and actuators. This foundational knowledge is non-negotiable.

Interviewer: Is learning Ladder Logic enough for beginners?

Trevor Blevins: Ladder Logic is a great starting point because it’s visual and resembles electrical schematics, which many engineers find intuitive. But don’t stop there. Explore Function Block Diagram and Structured Text because complex applications often demand these advanced languages.

Advanced Knowledge for Industrial Applications

Interviewer: Beyond the basics, what advanced skills should programmers develop?

Trevor Blevins: Industrial automation isn’t just about programming; it’s about integrating systems. You need to understand communication protocols like Modbus and Ethernet/IP. They’re essential for connecting PLCs to other devices. Additionally, I learned about SCADA and HMI integration. These systems give operators real-time control and monitoring capabilities.

Interviewer: How necessary is safety knowledge in PLC programming?

Trevor Blevins: Safety is paramount. Compliance with standards like IEC 61508 ensures systems run reliably and protect operators and equipment. You also need to program safety interlocks and fail-safes. Neglecting this can have catastrophic consequences.

How to Gain Knowledge of PLC Programming

Acquiring programming expertise for automation systems involves combining theoretical knowledge with practical experience.

Resources for Learning PLC Programming

Interviewer: Trevor, what resources do you recommend for someone eager to learn automation programming?

Trevor Blevins: Books and manuals from manufacturers are a great starting point. Online courses are also helpful, especially those that include hands-on exercises. Simulators like TIA Portal or RSLogix are excellent for practice. Additionally, online forums are invaluable; I’ve seen beginners solve complex problems by discussing them in these communities.

Interviewer: Are certifications worth pursuing?

Trevor Blevins: Absolutely. Certifications from Siemens or Rockwell Automation validate your skills and open doors in the job market. Many employers prioritize certified programmers.

Hands-On Experience and Training

Interviewer: What’s the best way to get hands-on experience?

Trevor Blevins: Internships and apprenticeships are fantastic because they expose you to real-world challenges. But even if you can’t access those, invest in a basic PLC kit and experiment. Try controlling lights or motors. You’ll learn a lot from troubleshooting your setups.

Interviewer: Can workshops or boot camps accelerate learning?

Trevor Blevins: Yes, they’re invaluable. Bootcamps condense years of learning into weeks. You’ll also network with industry professionals, leading to job opportunities or mentorship.

Conclusion

Mastering programming for automation systems is a journey that combines foundational knowledge, advanced skills, and practical application. By understanding the core components, exploring advanced industrial concepts, and engaging in hands-on training, you can develop expertise that positions you as a skilled programmer in this field.

Trevor Blevins emphasizes the importance of consistent practice and staying curious. “The industry evolves rapidly,” he says. “Keep learning, stay adaptable, and never hesitate to ask questions. That’s how you grow as a programmer.”

Whether through self-learning, formal training, or industry collaboration, the key to success lies in dedication and a willingness to tackle challenges head-on.

Frequently Asked Questions

PLC stands for Programmable Logic Controller, which is an industrial digital computer designed to automate specific processes or machines by executing a set of instructions.

PLC skills refer to the ability to program, troubleshoot, and maintain PLC systems used in industrial automation, ensuring efficient operation of machinery and processes.

The concept of PLC involves using a programmable system to monitor and control industrial processes automatically, improving efficiency, reliability, and safety in production environments.