OIYA Portfolio

Explore the OIYA Portfolio, showcasing our innovative automation solutions that revolutionize efficiency and safety across industries.

HomePortfolio

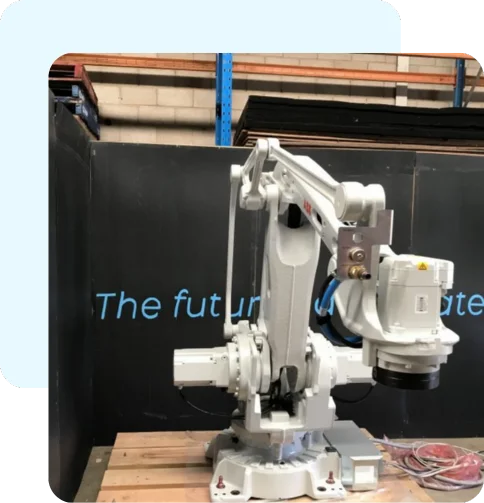

Materials Handling Automation signifies the evolution of manufacturing lines towards efficiency and safety.

OIYA’s integration of dual robot systems exemplifies our commitment to enhancing client manufacturing environments.

By automating the process of picking and placing products for shipping, we not only mitigate the risks associated with manual labor but also repurpose human resources for more critical tasks.

Our approach, involving simulated offline testing, ensures a seamless transition to automation without impacting the client's productivity.

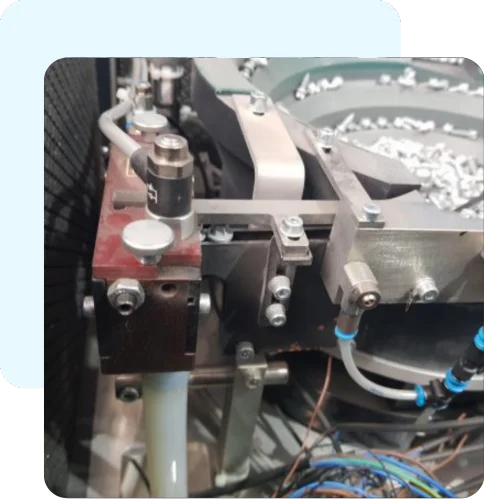

The Screw Pier Tube Processing System stands at the forefront of innovation for the construction industry, streamlining the preparation of tubes for screw piers.

From cutting tubes of varying lengths and diameters to drilling and packaging, our system embodies precision and efficiency with a cycle time of less than one minute per pipe.

This automation not only accelerates production but also enhances the consistency and quality of the finished product.

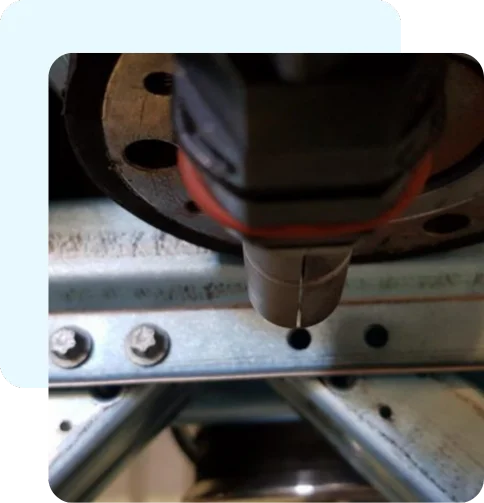

At the core of OIYA’s technological advancements is the Automated Screw Fastening System, a marvel of engineering that integrates a 2-axis servo motor with a customised screwdriver and bowl feeder.

Designed to expedite the assembly process, this system can fasten screws in just 3 seconds, with ongoing improvements aimed at further reducing this time.

This system exemplifies our pursuit of excellence and our commitment to delivering cutting-edge solutions to our clients.

The Gantry Robot is an integral component of steel processing lines, designed to optimize efficiency and accuracy.

With its sophisticated control over both horizontal and vertical motions, coupled with pneumatic finger grippers, the robot expertly transfers beams between conveyors.

This automation solution not only enhances production speed but also ensures the safety and precision of the process.

Confronting the challenges posed by an imported pharmaceutical blister pack machine, OIYA embarked on a comprehensive upgrade to meet local standards and exceed client expectations.

Enhancements included performance improvements and the integration of a barcode scanning system for leaflet validation, ensuring the correct information accompanies each product.

This project underscores our capability to tailor solutions to specific regulatory and operational requirements.

Our portfolio is complemented by an extensive gallery of images showcasing our diverse projects.

From the intricacies of materials handling automation to the precision of the Screw Pier Tube Processing System, and the reliability of our Gantry Robot, each image captures the essence of OIYA's commitment to innovation and excellence in automation.

Through these endeavors, OIYA continues to set new benchmarks in the field of automation, demonstrating our unwavering dedication to enhancing the efficiency, safety, and quality of our clients' operations.