OIYA Steel Frame Automation

OIYA Steel Frame Automation service streamlines your construction projects with advanced, precision-engineered solutions for unparalleled efficiency and accuracy.

ServiceSteel Frame Automation

Materials Handling typically refers to the automation of manufacturing lines where a mass produced product is manufactured.

Traditionally the product is picked by an operator and placed on a pallet or stack ready for shipping to the client as the finished product.

As a manual task, the labour required and the inherent WHS risks associated with it make this task attractive to automate. As a robot system integrator this task presents an attractive opportunity to be replaced by an automated system. Firstly it increases the safety of the client’s manufacturing as well as freeing up labour units to be redeployed within the factory to complete other manual tasks.

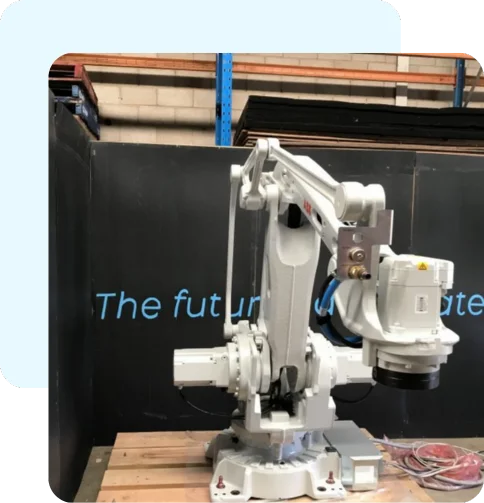

The dual robot system shown here was setup in our factory to complete the simulated offline testing where we picked and placed the client’s product. This approach avoided any downtime at the client’s site where we were able to quickly install and transition to automation without negatively impacting production.

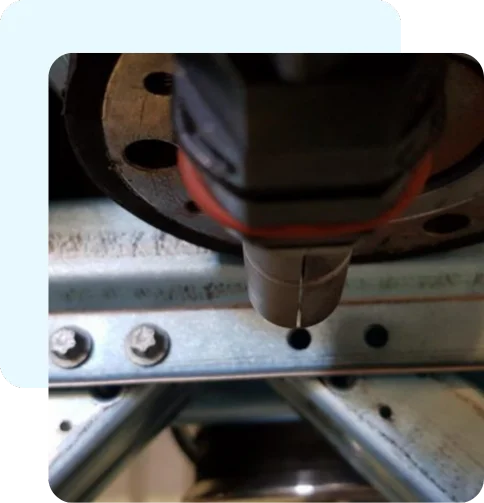

As part of a larger system the screw fastening system automatically loads and fastens screw into two pieces of metal

The screwdriver is attached to a 2 axis servo motor controlled linear drive system that positions the screwdriver inline with the hole and then fastens as the two pieces of material together

The screws are automatically fed to the screwdriver by a bowl feeder.

The cycle time to fasten on screw is approximately 3 seconds. Improvements are in progress to reduce this time further.

The bowl feeders and screwdriver are customised off the shelf items manufactured by a German engineering company.

The gantry robot is part of a steel processing line. The gantry robot picks a beam up off of one chain conveyor and places onto one of two roller conveyors.

The robot comprises of: