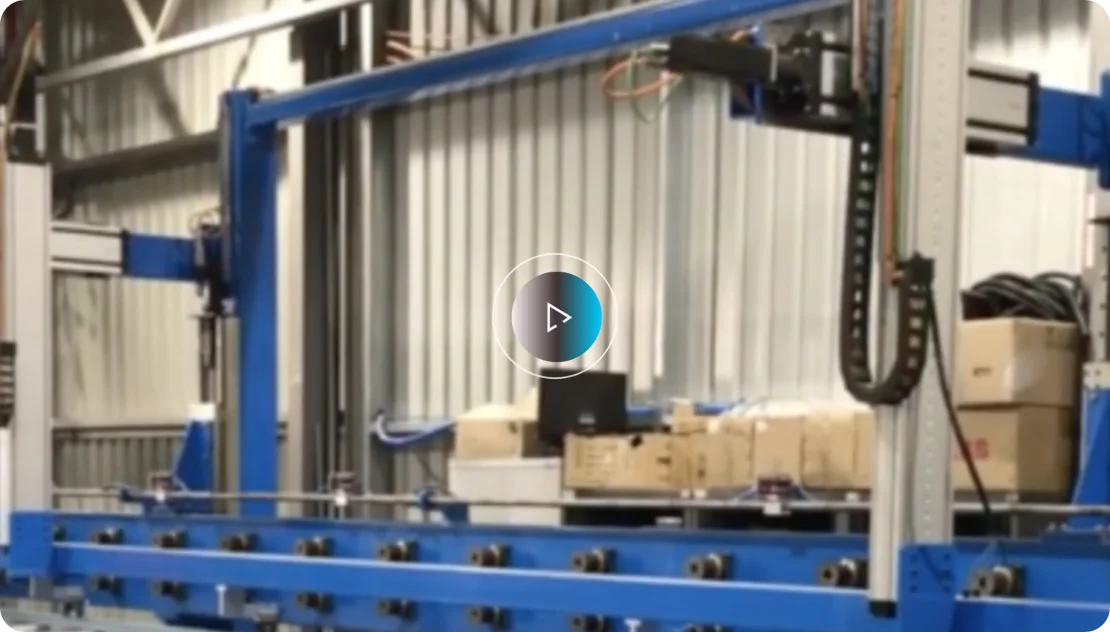

OIYA Gantry Robot Service

At OIYA, we take pride in enhancing industrial automation with our advanced Gantry Robot service, a key component in steel processing lines designed to optimize efficiency and precision. Our Gantry Robot is engineered to seamlessly integrate into your operations, offering a robust solution for material handling that reduces manual labor and improves workflow.

ServiceGantry Robot Service