Yes, you can learn PLC on your own through online resources, tutorials, and hands-on practice with simulation software or real PLC systems.

PLC Controller Programming: What Is It?

Introduction to PLC Controller Programming

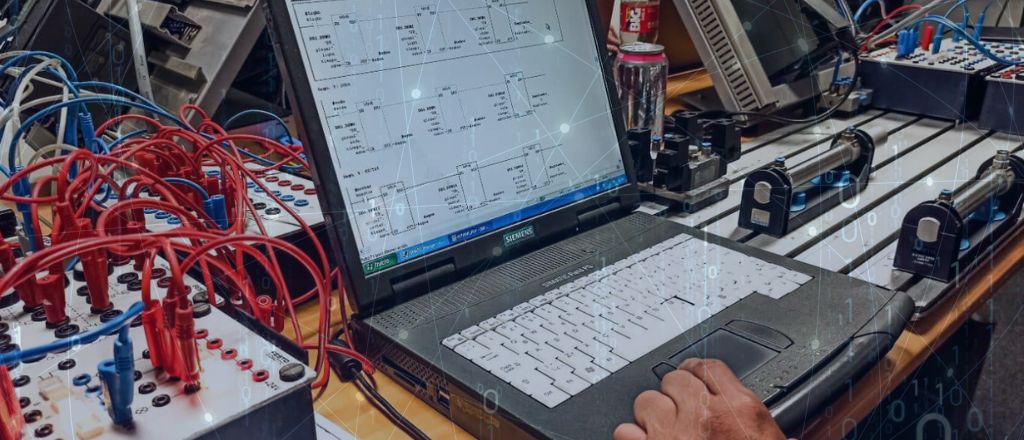

PLC (Programmable Logic Controller) programming involves designing and implementing control logic that governs automated machinery and processes. Engineers and technicians use PLCs to replace traditional relay-based systems, enabling precise, reliable, and efficient control of industrial equipment. PLC controllers excel in automation environments, including manufacturing, chemical processing, and packaging systems.

A PLC controller is a robust digital computer that operates in real-time. It receives sensor inputs, processes the data according to the programmed logic, and triggers outputs to control devices like actuators, motors, and alarms. PLC programming involves creating logical instructions using specialized software that translates commands into machine-readable code. This process empowers industries to achieve consistent, safe, and error-free operations.

Key Skills for PLC Controller Programmers

Effective PLC programming demands technical expertise, problem-solving abilities, and practical experience. Essential skills include:

- Understanding of PLC Hardware: Programmers must comprehend the architecture of PLCs, including input/output (I/O) modules, processors, and communication interfaces.

- Knowledge of Programming Languages: Familiarity with languages like Ladder Logic (LD), Function Block Diagram (FBD), Structured Text (ST), and Sequential Function Charts (SFC) is crucial. Each language suits different applications and complexity levels.

- Control System Design: Programmers need a solid grasp of control system principles, such as feedback loops, timers, counters, and PID controllers, to design effective automation systems.

- Debugging and Troubleshooting: Analyzing errors, debugging programs, and troubleshooting hardware are vital to ensuring system reliability.

- Communication Protocols: Understanding protocols like Modbus, Ethernet/IP, and Profibus is essential for integrating PLCs with other devices and networks.

- Attention to Safety Standards: Knowledge of industry standards and safety regulations ensures compliant and hazard-free designs.

By mastering these skills, programmers can design efficient and robust control systems tailored to specific industrial needs.

Programming a PLC Controller

Step-by-Step Guide to PLC Controller Programming

- Define the System Requirements: Outline the system’s objectives and operational requirements. Gather details about inputs (e.g., sensors, switches) and outputs (e.g., motors, actuators). Define the desired sequence of operations and safety considerations.

- Select the Right PLC Hardware: Choose a PLC model compatible with the system’s complexity and scalability needs. Consider factors such as the number of I/O points, processing speed, and communication interfaces.

- Develop a Control Strategy: Create a functional description of the system. Map out the logical sequence of operations, including conditions for activating inputs and outputs. Use tools like flowcharts or diagrams for clarity.

-

Write the PLC Program: Open the PLC programming software and configure the hardware settings. Develop the Program using a suitable programming language. For instance:

- Use Ladder Logic for straightforward, relay-like diagrams.

- Use Structured Text for complex mathematical or data manipulation tasks.

Employ features like timers, counters, and comparisons to define precise operational control.

- Simulate the Program: Test the Program in a virtual environment to validate its logic. Simulations help identify potential issues without risking equipment or personnel safety.

- Download the Program to the PLC: Transfer the validated Program to the PLC hardware. Use the communication interface, ensuring the connection matches the chosen protocol.

- Test the System: Conduct on-site testing to verify that the system performs as intended. Monitor inputs, outputs, and overall functionality. Fine-tune the Program as necessary to resolve discrepancies.

- Document the Program: Maintain detailed documentation, including annotated code, wiring diagrams, and system descriptions. Comprehensive records simplify maintenance and troubleshooting.

- Deploy and Monitor: Activate the PLC-controlled system in a live environment. Continuously monitor its performance to ensure stability and efficiency. Implement periodic updates or optimizations as needed.

Common Pitfalls and How to Avoid Them

- Inadequate Planning: Many issues arise from insufficient system design or undefined requirements. Avoid this by dedicating time to thorough planning and requirement gathering.

- Overcomplicated Code: Complex programming increases the risk of errors. Simplify code by modularizing logic into manageable sections and using descriptive labels.

- Neglecting Safety Measures: Failing to incorporate safety protocols can lead to hazardous conditions. Include emergency stop functions, fault detection, and interlocks in your design.

- Ignoring Maintenance Needs: Programs without clear documentation or error-handling mechanisms complicate future maintenance. Include descriptive comments and design intuitive error-reporting features.

- Insufficient Testing: Deploying a program without rigorous testing can cause operational failures. Utilize simulations and extensive on-site testing to identify potential problems.

- Overlooking Scalability: Designing a system without considering future expansion limits its adaptability. Use scalable hardware and flexible programming techniques to accommodate growth.

- Communication Failures: Misconfigurations in communication protocols disrupt device interactions. Verify protocol settings and test connectivity before deployment.

- Inadequate Training for Operators: Operators unfamiliar with the PLC system may misuse it or fail to respond to alerts. Provide comprehensive training and user-friendly interfaces.

By addressing these pitfalls proactively, programmers can deliver efficient, safe, and reliable PLC systems.

Expert Insights: An Interview with Trevor Blevins

Interviewer: Trevor, thank you for joining us today. Can you start by explaining why PLC programming is critical in modern industry?

Trevor Blevins: Absolutely. PLC programming is at the heart of industrial automation. It ensures that machinery operates precisely, consistently, and safely. Without it, processes would rely on outdated manual controls or relay systems, which are less efficient and prone to errors. PLCs provide flexibility and scalability, essential for adapting to evolving industrial needs.

Interviewer: What is the most challenging aspect of programming a PLC controller?

Trevor Blevins: One of the biggest challenges is ensuring the Program is robust and failsafe. Industrial environments can be unpredictable, so you need to anticipate potential issues and design for fault tolerance. Another challenge is integrating different communication protocols, especially in complex systems with multiple devices.

Interviewer: Could you share a tip for avoiding common programming pitfalls?

Trevor Blevins: Before you start coding, plan thoroughly. A well-documented control strategy and a clear understanding of system requirements are essential. Always test your Program in a simulation environment, as catching errors is much safer and more cost-effective than testing it in a live system.

Interviewer: What trends do you see shaping the future of PLC programming?

Trevor Blevins: Integrating IoT and advanced data analytics is transforming PLC programming. We’re seeing more PLCs connected to cloud platforms for real-time monitoring and optimization. Another trend is the adoption of open-source programming environments, which offer more flexibility than traditional proprietary software.

Interviewer: Lastly, what advice would you give to someone starting their career in PLC programming?

Trevor Blevins: Focus on the fundamentals. Learn the core programming languages and get hands-on experience with hardware. Don’t hesitate to troubleshoot—it’s one of the best learning methods. I have always been curious because this field evolves rapidly with technology.

Conclusion

PLC controller programming is a cornerstone of industrial automation, enabling businesses to achieve precision, efficiency, and reliability. Success in designing robust control systems depends on a systematic approach, which includes understanding hardware, programming languages, and rigorous testing. Avoiding common mistakes and focusing on safety and scalability further enhances system performance. By mastering the principles and skills outlined in this guide, programmers can excel in creating innovative solutions that drive industrial progress.

Frequently Asked Questions

Control system programming is relatively simple for beginners with basic programming or electronics knowledge, but mastering it requires practice.

The main languages used in control system programming include Ladder Logic, Structured Text, Function Block Diagram, and Instruction List.

Begin by learning the basics of PLC hardware, programming languages (especially Ladder Logic), and use simulation software or beginner kits to practice real-world applications.