A PLC (Programmable Logic Controller) is a specialized computer used to control machines and processes in industries by executing programmed instructions.

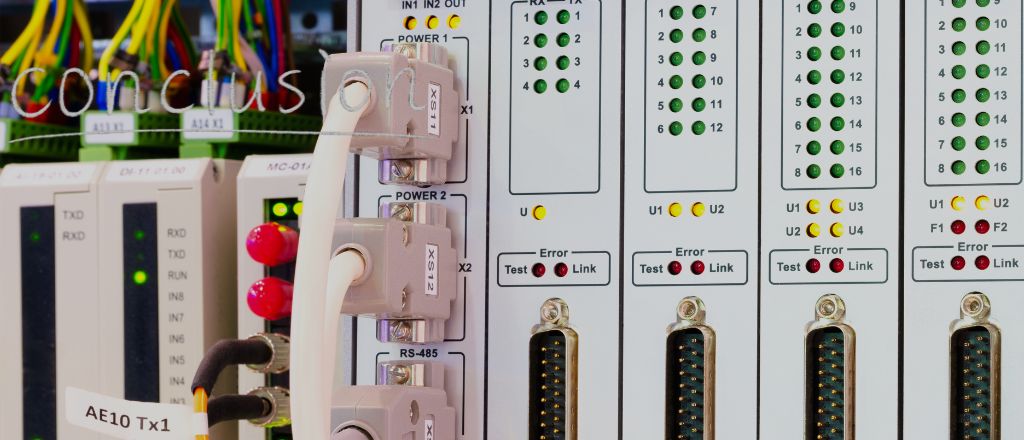

What is a PLC - A Programmable Logic Controller (PLC) is the backbone of industrial automation. It is a specialized computing device designed to monitor and control various electromechanical processes in manufacturing, robotics, and other industrial environments. Unlike general-purpose computers, PLCs are purpose-built to operate in harsh conditions and execute precise, time-sensitive tasks.

What is a PLC - Understanding PLCs

Definition and Function of a PLC

A PLC is a ruggedized digital computer used to automate electromechanical processes. It performs its functions by cyclically executing a series of programmed instructions. These instructions guide the PLC in monitoring input devices such as sensors, processing this information, and providing output to actuators and other control devices.

The key functions of a PLC include

- Input Monitoring: Collecting data from sensors and switches.

- Processing: Executing logic programs written in Ladder Logic or Structured Text.

- Output Control: Sending commands to actuators, motors, or other output devices to control a process.

PLCs can handle tasks like turning on a conveyor belt to complex operations involving multiple feedback loops and variable adjustments.

Interviewer: Trevor, could you elaborate on why PLCs are crucial in industrial settings?

Trevor Blevins: Absolutely. PLCs act as the central nervous system of any automated process. They bridge the gap between mechanical devices and digital control, enabling factories to run efficiently. Their reliability in adverse conditions and ability to process real-time data make them indispensable.

How PLCs Control Industrial Processes

PLCs control industrial processes by continuously monitoring inputs and making real-time decisions based on programmed logic. For instance, in an automated assembly line, sensors detect the presence of an object, and the PLC activates a robotic arm to pick and place the item. This sensing, processing, and acting cycle occurs in milliseconds, ensuring efficiency and precision.

Interviewer: Can you give an example of how PLCs improve efficiency in modern manufacturing?

Trevor Blevins: Sure. Take a bottling plant. Sensors detect bottle positions, and the PLC ensures that filling, capping, and labelling occur in perfect synchronization. If a problem arises, such as a bottle missing a cap, the PLC halts the process and alerts operators, preventing wastage and downtime.

PLCs use their internal memory to store operational data and program logic. Manufacturers design PLCs to operate in extreme conditions, including high temperatures, vibrations, and electrical noise, which makes them ideal for industrial environments. Engineers can expand their functionality thanks to their modular nature by adding new input/output modules.

The Evolution of PLCs

Early PLCs vs. Modern PLCs

The first PLC emerged in the late 1960s as replacements for relay-based control systems. These early PLC were simple devices with limited memory and processing power, designed primarily to replace hard-wired relays. Engineers programmed early PLC using punched tapes or basic text-based interfaces, limiting their applications to straightforward control tasks.

Interviewer: Trevor, how would you describe the leap from early PLC to modern ones?

Trevor Blevins: The shift has been monumental. Early PLC functioned as glorified switchboards. Modern PLC operate as miniature powerhouses, running complex algorithms, managing entire facilities, and communicating with cloud platforms. The difference compares a typewriter to a supercomputer.

Modern PLC, however, have transformed into sophisticated computing devices. They feature

- Increased Processing Power: It supports complex algorithms and high-speed data processing.

- Enhanced Connectivity: Integrating with Ethernet, wireless, and industrial communication protocols like Modbus and Profinet.

- User-Friendly Interfaces: Advanced Human-Machine Interfaces (HMIs) provide seamless programming and monitoring.

- Scalability: Allowing modular expansions to suit varying industrial needs.

Technological Advancements in PLCs

Technological advancements have redefined the capabilities of PLCs, aligning them with Industry 4.0 standards. These innovations include:

- Integration with IoT: Modern PLCs connect to IoT platforms, enabling remote monitoring, predictive maintenance, and data analytics.

- Cloud Connectivity: Operators can access and manage PLCs remotely through cloud-based interfaces, ensuring flexibility and efficiency.

- Artificial Intelligence (AI) Integration: Advanced PLCs use AI algorithms to optimize processes, predict faults, and enhance decision-making.

- Improved Cybersecurity: With increased connectivity comes the need for robust cybersecurity measures. Modern PLCs incorporate encryption and secure communication protocols to protect industrial networks.

- Miniaturization: Smaller and more efficient PLCs save space while delivering higher performance.

Interviewer: What is the most exciting development in PLC technology right now?

Trevor Blevins: Without a doubt, the integration of AI and IoT. These technologies allow for more intelligent and more responsive systems. For example, AI can analyze process data in real-time, making predictive adjustments that improve efficiency and reduce downtime.

These advancements have expanded the applications of PLCs, making them indispensable in smart manufacturing, energy management, and automated systems.

Conclusion

PLCs have revolutionized industrial automation by providing reliable, scalable, and efficient control solutions. From their humble beginnings as simple relay replacements to their current status as IoT-enabled devices, PLCs have adapted to meet the evolving demands of industries worldwide. Their ability to handle complex tasks, integrate with modern technologies, and operate in harsh environments makes them essential to modern industrial processes. As technology advances, the role of PLCs will undoubtedly grow, shaping the future of automation and intelligent systems.

Interviewer: Any final thoughts, Trevor?

Trevor Blevins: PLCs are more than machines; they enable innovation. PLCs will remain at the heart of this transformation as industries evolve, driving us toward a more connected and automated future.

Frequently Asked Questions

The main purpose of a PLC is to automate industrial processes, monitor inputs, and control outputs, ensuring efficient and reliable operation of machinery.

A PLC (Public Limited Company) is a type of company that offers shares to the public, whereas a private company does not.

A PLC operating system is the software that runs on a PLC, managing hardware and executing the control programs that drive automation processes.