Yes, robotic welders are worth it because they increase efficiency, improve accuracy, and reduce production costs over time.

Welding robots are now a part of modern factories. They improve the speed and accuracy of welding. Factories use more technology to get work done faster. These robots ensure high-quality welding.

Welding Robots What They Are and How They Work

A robotic system automates tasks that were traditionally handled manually. Using advanced technology, these machines perform tasks with greater speed and precision. They are widely adopted across industries to improve efficiency and productivity in various applications.

How Welding Robots Have Changed Modern Factories

Over time, robots have become more advanced and efficient. They help companies in areas like construction and storage. These robots make it easier for businesses to get more done and improve their work processes.

Welding Robots vs. Manual Work: Why Automation Is Better

Automated machines for joining materials offer significant advantages over manual labor. They ensure consistent precision with every task, minimizing errors. This reliability helps businesses save time and resources, ultimately boosting overall productivity.

How Welding Robots Make Work Faster and Easier

Automated systems streamline tasks that are time-consuming and labor-intensive, enabling faster and more efficient workflows. With these advanced solutions, companies can complete projects more quickly while maintaining high-quality standards.

Cobots: Robots That Work with People to Help with Welding

Cobots are advanced machines designed to collaborate with humans in various tasks. In this field, they assist workers by simplifying complex jobs and enhancing safety. Cobots excel at handling small, precise tasks while working seamlessly alongside people.

Using Welding Robots to Do More Work

Using automated systems for joining processes allows companies to complete tasks more efficiently. These advanced machines improve workflow in factories and other industries, enabling faster production and smoother operations.

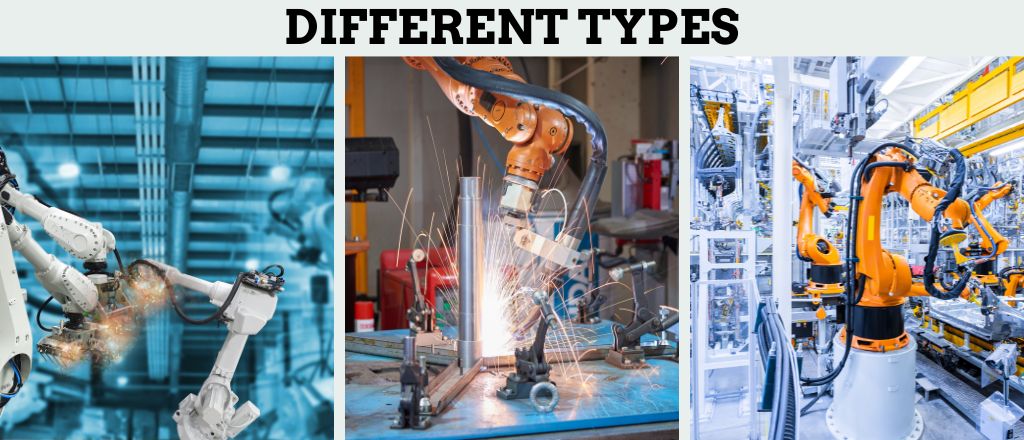

Different Types of Welding Robots and What They Do

Each type handles different tasks, from simple to complex jobs.

Arc Welding Robots: Good for Complicated Welding Jobs

Robots designed for arc-based tasks are ideal for handling complex jobs. They are highly beneficial in industries such as construction and steel framing, ensuring every joint is both durable and accurately crafted.

Spot Welding, MIG MAG, and TIG: Important Robot Jobs

These advanced machines are capable of various joining techniques, including spot, MIG MAG, and TIG methods. MIG MAG, in particular, is highly effective for joining metals quickly and efficiently. These automated systems excel in performing these processes with precision and consistency.

Laser Welding Robots: Perfect for Detailed Work

This type of robots are great for industries that need detailed and precise work. Manufacturing companies often use them because they are fast and accurate.

Why Welding Robots Are Important in Factories

Those type of robots bring many benefits, like saving money and working faster. They are useful in industries such as construction and manufacturing.

Welding Robots in Steel Framing and Construction

In steel framing and construction, robo welder are helpful. They can do precise work quickly, making sure that every weld is perfect. This is especially important in building strong structures and increasing productivity.

Flexible Welding Solutions for Warehousing and Logistics

In warehousing and logistics, automated machines assist in assembling equipment and handling related tasks. Their flexibility allows them to perform a variety of joining processes, contributing to efficient operations and streamlined workflows.

How Welding Robots Save Money and Do Quality Work

Automated systems for joining materials help businesses cut costs by minimizing reliance on manual labor while increasing productivity. These advanced machines also ensure precision and deliver results that meet strict industry requirements.

How Welding Robots Make Factories More Productive

These advanced machines enable factories to increase productivity by completing tasks efficiently. This allows companies to finish projects more quickly while maintaining high-quality standards.

How Robots Improve Welding Efficiency

These machines enhance factory efficiency by performing repetitive tasks with consistent precision and reliability. Integrating these systems allows companies to increase production speed and output while maintaining high-quality standards.

Getting More Work Done with Automated Welding

Automated solutions let companies do more work faster. By using these solutions, factories can produce more products without needing extra workers.

Cobots in Welding: The Future of Welding in Factories

Collaborative robots are transforming metalwork processes, offering a safe and efficient way to work alongside people. These versatile machines handle a variety of tasks with precision and adaptability.

How Cobots Make Welding Easier and More Flexible

Cobots simplify the joining process with their flexibility and precision. They assist workers by handling intricate and detailed tasks, enhancing both speed and safety during operations.

Cobots in Welding: Safe and Accurate Systems

Cobots are built to operate safely alongside humans. They enhance tasks by improving precision and creating a safer environment for workers, ensuring high-quality results.

OIYA: Leading the Way in Welding Automation

OIYA provides advanced collaborative robots for businesses across various industries, including construction, logistics, and manufacturing. Our solutions are designed to meet the unique needs of each sector with precision and efficiency.

Welding Robots and Cobots for the Future

OIYA is advancing businesses into the future with innovative robotic solutions. These machines streamline tasks, enhancing speed, safety, and cost-effectiveness in manufacturing processes.

Tailored Welding Solutions for Manufacturing, Construction, and Logistics

OIYA designs tailored industrial automation solutions for applications in manufacturing, construction, and logistics. By offering advanced automation systems and versatile solutions, OIYA enables businesses to enhance productivity and efficiency through cutting-edge technology.

Contact us today for a free quote or to book our services.

Frequently Asked Questions

Industries commonly use robots like the Fanuc ArcMate or ABB IRB series for welding.

The biggest disadvantage is the high cost at the start. You also need skilled workers to maintain and program the robots.

Robots aren't completely replacing welders. They handle repetitive tasks so human welders can focus on more complicated work.